From Yarn to Worldwide Launch: How Panada Fashion Turns a Designer’s 3-Second Idea into a 7-Day Reality

The moment a sketch lands at Panada Fashion, a creative journey begins. We know that if the lines and colors dreamed up by a designer cannot be translated quickly, precisely, and sustainably into fabric and finished garments, even the most brilliant idea remains nothing more than ink on paper. So Panada Fashion has built a “digital-green artery” that runs from our yarn lab all the way to the customs dock, turning imagination anywhere in the world into tangible merchandise.

1. Yarn Library: Translating Inspiration into Fiber

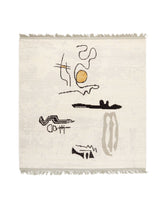

At our headquarters in Nantong, the “Yarn Library” houses 2,400 fully traceable yarns. A 3-D scanner converts any color block on a designer’s sketch into spectral data within five minutes, then finds the closest match among those yarns. Want a “moss-after-rain” pajama set? The AI color-matching system will recommend a 70 % Lenzing TENCEL / 20 % organic cotton / 10 % recycled-polyester blend that reveals a subtle, shimmering green shift under different lights. Once the yarn is locked, an auto-winder produces a sample cone in 30 minutes, letting the designer feel “the fiber form of inspiration” the same day.

2. Digital Twin: From Paper Pattern to Garment in 24 Hours

With the yarn confirmed, the next step is pattern realization. Via CLO-SET 3-D software, the designer uploads the sketch and an immediate, rotatable digital avatar is generated. Pattern makers and designers co-edit in the cloud—raise the sleeve cap by 0.5 cm, deepen the neckline by 1 cm—and data sync instantly to the auto-cutter in Nantong. Twenty-four hours later, a 1:1 physical sample hangs in the designer’s live-stream studio, tolerance ≤ 1.5 mm.

3. Flexible Smart Manufacturing: Global Launch Starts at 80 Pieces

Traditional factories shun small runs; Panada turns “small” into a superpower. The MES system splits an 80-piece order into 20 micro-batches that run concurrently on the same line. Four interchangeable modules—digital print, embroidery, dip-dye, and DTG—snap together like Lego bricks, so limited editions never sacrifice craftsmanship. Last year Shanghai label MONSOON tested 120 dip-dyed pajamas on a North-American crowdfunding platform; they sold out in 72 hours. Panada delivered the 2,000-piece restock in six days, helping MONSOON win Kickstarter’s “We Love Sleepwear” category.

4. Green Passport: Delivering Creativity Sustainably

From yarn onward, every garment receives a “green passport.” GOTS organic cotton, FSC-certified TENCEL, and GRS recycled polyester are barcode-scanned at intake. Solar power covers 42 % of plant demand, and each meter of fabric emits 35 % less CO₂ than the industry average. At customs, the system auto-generates an ESG report that designers can paste straight into their brand story—customers simply scan the QR code to see the garment’s conscience.

5. Global Express: On Shopify in 48 Hours

While the ship is still at sea, Panada’s cross-border cloud warehouses in Los Angeles, Rotterdam, and Dubai are already stocked. One click in the designer dashboard auto-creates a Shopify SKU; consumers receive their order within 48 hours. A “zero-inventory” model is also available: designers can pre-sell in 3-D, then trigger production only after data proves demand—turning creativity into cash flow.

Epilogue: Setting Creativity Free from Supply-Chain Chains

At Panada Fashion, designers need only focus on inspiration; everything else is on us. From the exact hue of the first yarn to the last strip of tape on the shipping carton, every step is standardized, digitized, and sustainable. When supply works like tap water, the river of creativity can reach a wider ocean. Your next sketch is waiting for ink—let’s turn it into fabric.